-

Bird Repellers: Features & Applications in the Power Industry

Features:

- Multi-Sensor Integration: Combines Doppler radar detection, acoustic sensors, ultrasonic waves, and flashing lights to deter birds through auditory and visual stimuli, ensuring comprehensive protection.

- Low-Power & Smart Operation: Utilizes advanced microcontrollers and energy-efficient designs for 24/7 operation in remote or off-grid power facilities.

- Adaptive Deterrence: Employs AI-driven responses, such as mimicking predator calls (e.g., hawks) or gunshots, tailored to bird species and environmental conditions.

- Durability & Weather Resistance: Designed to withstand harsh outdoor environments, including high-voltage zones and extreme weather, using corrosion-resistant materials.

Applications in Power Industry:

- Transmission Towers: Prevents bird nesting and collisions, reducing risks of short circuits or equipment damage.

- Substations: Protects critical infrastructure from bird-induced contamination (e.g., droppings) and electrical faults.

- Wind Farms: Safeguards turbine blades and towers from bird strikes, minimizing operational disruptions.

- Emergency Maintenance: Deployed temporarily during repairs to ensure worker safety and uninterrupted operations.

-

Applications:

- Substation Wiring: Connects busbars, transformers, and switchgear to ensure reliable power distribution.

- Overhead Transmission Lines: Joins conductors in towers/pylons for uninterrupted high-voltage grid operations.

- Renewable Energy Systems: Links solar panels, wind turbines, and battery storage in solar/wind farms.

- Underground Distribution: Seals and protects cable joints in direct-buried or ducted networks.

- Industrial Power Networks: Facilitates connections in factories, data centers, or mining operations with heavy machinery.

- Emergency Repairs: Enables rapid restoration of damaged power lines during outages or disasters.

-

Cable Mesh Sock: Features & Applications in the Power Industry

Features:

- Flexible & Durable: Woven from high-strength stainless steel or synthetic fibers, it adapts to cable contours while resisting abrasion and mechanical stress.

- Distributed Load Design: Evenly spreads pulling force across the cable surface, preventing insulation damage during installation.

- Corrosion & Weather Resistance: Ideal for harsh environments (e.g., underground, marine) with coatings that repel moisture, chemicals, and UV exposure.

- Universal Compatibility: Adjustable to various cable diameters (e.g., LV to EHV) and types (armored, submarine, or fiber-optic).

- Reusable & Lightweight: Enhances cost-efficiency and ease of handling for repetitive tasks.

Applications:

- Cable Pulling: Safely installs power cables in conduits, ducts, or direct-buried systems for substations, wind farms, or urban grids.

- Submarine Cable Deployment: Protects underwater cables during laying and retrieval in offshore energy projects.

- High-Voltage Installations: Secures large-diameter HV/EHV cables in transmission towers or industrial plants.

- Temporary Repairs: Stabilizes damaged cables for emergency fixes without immediate replacement.

- Renewable Energy: Facilitates solar/wind farm grid connections by handling sensitive cabling in rugged terrains.

-

Cable Swivel: Features & Applications in the Power Industry

Features:

- 360° Rotation & Torque Relief: Enables smooth rotation under tension, preventing cable twisting and minimizing stress during installation.

- High Load Capacity: Built with hardened steel or alloy components to withstand heavy-duty pulling forces (e.g., up to 50+ tons).

- Corrosion-Resistant: Coated or stainless-steel construction ensures durability in harsh environments (e.g., marine, underground).

- Universal Compatibility: Adaptable to various cable types (HV, submarine, fiber-optic) and diameters via modular attachments.

- Low-Friction Design: Integrated bearings or lubricated joints reduce wear, extending operational lifespan.

Applications:

- Cable Pulling Operations: Critical for installing long-span overhead lines, substation wiring, or underground HV cables without torsional damage.

- Submarine Cable Laying: Allows free rotation during deployment/retrieval of undersea power or communication cables in offshore wind farms.

- Transmission Tower Stringing: Maintains alignment and reduces kinking when stringing conductors across towers or pylons.

- Maintenance & Repair: Facilitates safe cable repositioning or replacement in confined spaces (e.g., ducts, tunnels).

- Renewable Energy Projects: Essential for solar/wind farm grid connections requiring precise cable routing on uneven terrain.

-

Conduit Rodder: Features & Applications in the Power Industry

Features:

- High-Strength & Flexible: Constructed from durable materials like fiberglass or steel, it bends smoothly through conduits without breaking, even in complex layouts.

- Anti-Snag Design: Equipped with tapered tips or rotating heads to navigate bends, debris, or junctions in underground cable ducts.

- Corrosion-Resistant: Ideal for humid or chemically aggressive environments, ensuring longevity in underground power systems.

- Modular & Extendable: Segments can be linked to reach long distances (e.g., 100+ meters), adapting to deep or sprawling conduit networks.

- Ergonomic Handling: Lightweight and fitted with grip-friendly handles for efficient manual operation.

Applications:

- Cable Installation: Pulls wires or cables through conduits in substations, switchyards, or underground power grids.

- Fault Location: Assists in threading inspection tools or sensors to identify blockages/damage in buried conduits.

- Maintenance & Upgrades: Facilitates retrofitting old systems with new cables without trenching, minimizing downtime.

- HV Grids: Critical for routing high-voltage cables in industrial plants or urban transmission networks.

-

Disc Warning Tape: Features & Applications in the Power Industry

Features:

- High Visibility – Bold colors (e.g., red, yellow) with reflective strips or printed warnings (e.g., “DANGER – HIGH VOLTAGE”) ensure clear visibility in low-light conditions.

- Durable Material – UV-resistant, waterproof, and tear-proof polymers withstand harsh outdoor environments and long-term exposure.

- Compliance – Meets industry safety standards (e.g., OSHA, IEC) for electrical hazard marking.

- Customizable – Allows printing of voltage levels, utility logos, or multilingual warnings for targeted communication.

Applications:

- Underground Cable Marking – Flags buried power lines during excavation to prevent accidental strikes.

- Hazard Zone Demarcation – Secures perimeters around transformers, substations, or live equipment.

- Temporary Work Sites – Marks off maintenance areas, overhead line repairs, or construction zones.

- Asset Protection – Alerts personnel to restricted access points near critical electrical infrastructure.

-

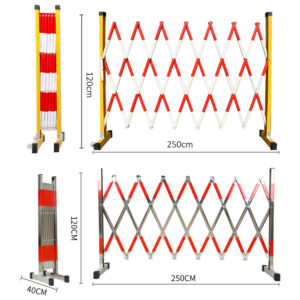

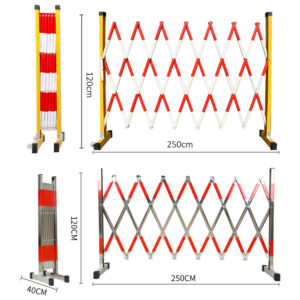

Fiberglass Extension Fence: Features & Applications in the Power Industry

Features:

- Non-Conductive & Safe: Made of fiberglass-reinforced polymer, it provides excellent electrical insulation, preventing accidental currents in high-voltage environments.

- Weather-Resistant: UV-resistant and impervious to moisture, corrosion, or extreme temperatures (-50°C to 120°C), ensuring durability in harsh outdoor conditions.

- Lightweight & Portable: Easy to install, relocate, and store, ideal for temporary or dynamic power projects.

- High Visibility: Often paired with bright warning strips or reflective markers to enhance safety awareness.

- Low Maintenance: Resists rust, chemicals, and pests, reducing lifecycle costs.

Applications:

- Substation Barriers: Safeguards equipment and personnel by isolating live components.

- Transmission Line Perimeter Control: Secures corridors around overhead lines during maintenance or construction.

- Temporary Hazard Zoning: Creates visible boundaries for excavation sites or exposed cables.

- Wildlife Deterrence: Prevents animals from contacting energized infrastructure in rural areas.

-

G210 D-Type Shackle: Features & Applications in the Power Industry

Features:

- High Load Capacity: Forged from heat-treated alloy steel, rated for heavy-duty lifting (e.g., 10+ tons), ensuring reliability in critical power infrastructure projects.

- Corrosion Resistance: Galvanized or stainless-steel finish protects against rust, UV exposure, and harsh environments (e.g., coastal or industrial sites).

- D-Shape Design: Provides secure side-load stability and easy attachment to rigging hardware, cables, or slings.

- Safety Pin Mechanism: Bolt-type pin with a safety collar prevents accidental opening during operations, complying with OSHA and IEC safety standards.

- Compact & Lightweight: Optimized for easy handling in confined spaces (e.g., substations, transmission towers).

Applications:

- Equipment Lifting: Secures transformers, circuit breakers, or switchgear during installation/maintenance.

- Transmission Tower Assembly: Connects guy wires, insulators, or conductors in overhead line construction.

- Cable Tensioning: Anchors pulling ropes or winches during underground cable laying or HV line stringing.

- Temporary Rigging: Supports temporary structures or safety nets in power plant upgrades or disaster recovery.

- Renewable Energy: Used in wind turbine rigging or solar farm installations for component hoisting.