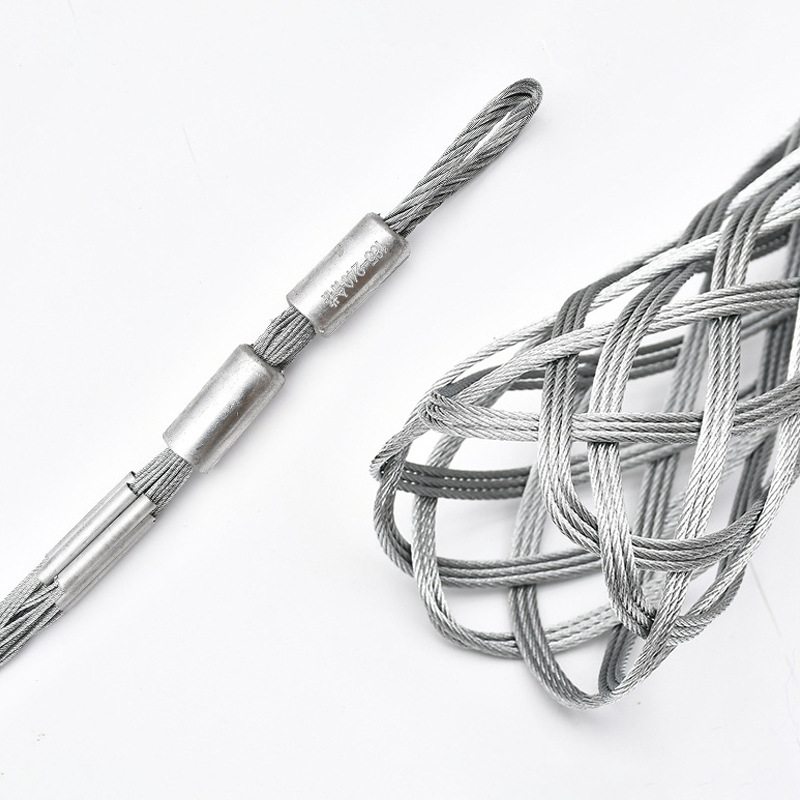

Cable Mesh Sock: Features & Applications in the Power Industry

Features:

- Flexible & Durable: Woven from high-strength stainless steel or synthetic fibers, it adapts to cable contours while resisting abrasion and mechanical stress.

- Distributed Load Design: Evenly spreads pulling force across the cable surface, preventing insulation damage during installation.

- Corrosion & Weather Resistance: Ideal for harsh environments (e.g., underground, marine) with coatings that repel moisture, chemicals, and UV exposure.

- Universal Compatibility: Adjustable to various cable diameters (e.g., LV to EHV) and types (armored, submarine, or fiber-optic).

- Reusable & Lightweight: Enhances cost-efficiency and ease of handling for repetitive tasks.

Applications:

- Cable Pulling: Safely installs power cables in conduits, ducts, or direct-buried systems for substations, wind farms, or urban grids.

- Submarine Cable Deployment: Protects underwater cables during laying and retrieval in offshore energy projects.

- High-Voltage Installations: Secures large-diameter HV/EHV cables in transmission towers or industrial plants.

- Temporary Repairs: Stabilizes damaged cables for emergency fixes without immediate replacement.

- Renewable Energy: Facilitates solar/wind farm grid connections by handling sensitive cabling in rugged terrains.